1,137 Views

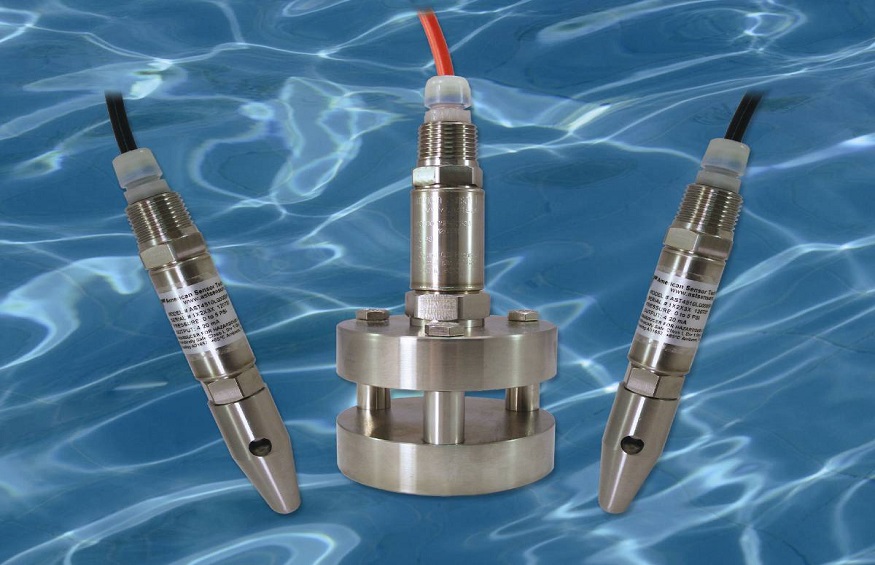

A liquid level sensor is a special device that is designed to detect and monitor the level of different types of fluids, including water, oil, and fuel. They can measure the level of liquid within a container or in its natural state.

There’s a huge variety of level sensors being manufactured today and they all belong to different industries – oil manufacturing plants, water treatment, power generating plants, pharmaceutical processes, petrochemical and chemical making refinery units, waste material handling industry, to name a few.

These sensors have become quite popular because they come with many benefits, such as

- Affordability

- Effort consumption

- Time efficiency

- Reliability

- Solid state design

Let’s take a look at three industries where these sensors are most commonly used and why:

Water Reservoirs

Level sensors are used to control and monitor the water levels in large water reservoirs to make sure processes like electricity and power generation can function optimally. These sensors have revolutionized many industrial operations.

Read more: Get Extra Assurance From Machinery And Software Specialists To Keep Running The Production

One of the most common types of liquid level sensors is the ultrasonic level sensor. It is used to detect the level of bulk solids and liquids with high viscosity.

Petrochemical Industry

These sensors are also common in petrochemical plants and they’re used to detect acidic and highly corrosive substances to make sure all the processes run efficiently. The petrochemical industry also utilizes ultrasonic liquid level sensors as they are non-contact sensors that remain protected when they’re exposed to corrosive substances.

Food and Beverage Industry

The food and beverage industry needs to uphold its reputation and make sure all the products are maintained up to a certain standard. This is where liquid level sensors come into play. These sensors are used to make sure the taste and texture of the products being manufactured stay consistent.

These devices are configured to monitor and detect the quality and consistency of beer, wine,milk, and other such substances.

Final Words

These are just a few of the many applications of liquid level sensors. When you’re selecting a level sensor, whether it’s a float sensor or a tank level gauge, you need to make sure it’s properly configured for the application and can survive in the environment it’s being exposed to. Make sure you’re maintaining the device regularly in order to increase its lifespan.